Lots of books have need for indexing tabs, books such as directories, address books, and ledgers. The marks for the index are placed along the fore-edge of the book. These can be half-round cuts called "thumb indexes" like those found on many dictionaries, or they can be strips of decreasing length that are cut out of the fore-edge. It is the latter I will show here.

Mary Sullivan of Crowing Hens Bindery in Nashville, TN reached out to me about this topic and provided the beautiful images of her German-style indexing shears and an image of the one described in Wm Atkins Account Book Binding - A Classic Article on Folding, Sewing, Equipment,..., pg 33. Note: This is text is available as Print on Demand and is excerpted from The Art and Practice of Printing by John Mason, edited by Wm. Atkins. Mary, by the way makes beautiful springback bindings. Check them out on her website. They open flat and are great for writing in.

|

Mary Sullivan's German Indexing Shears (top).

Hickock Index Shears from Atkins, pg 33 (below). |

Here is an image of shears, including the Registerschere from the 1928 catalog (pg. 38) for Braunwarth und Lüthke in Germany.

|

The Registerschere is 2nd from right. The elongated shape

between the handles shows the shape of the cutout. |

Both feature an adjustable gauge to set the depth of the cut. So, how would one go about using these.?

First, one would need to determine how many cuts need to be made. In most traditions there are letters that might be combined, or even left out. The indexing tabs would also need to be evenly spaced out to have a clean looking index along the foredge. So, how would one do this? Math by dividing height of textblock by number of tabs, or is there an easier way? Well, it so happens that there is, reusable even. As an aside, this idea can also be easily adapted for determining sewing stations of pretty much any number for any common book. Just lay the signature on the template so that the textblock aligns at top and bottom, then transfer marks.

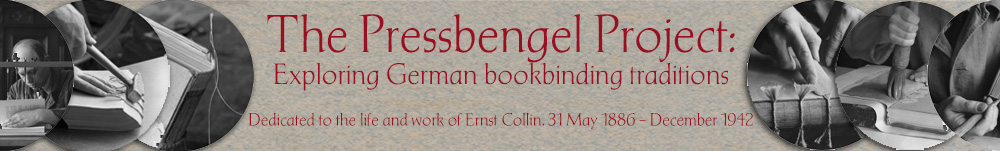

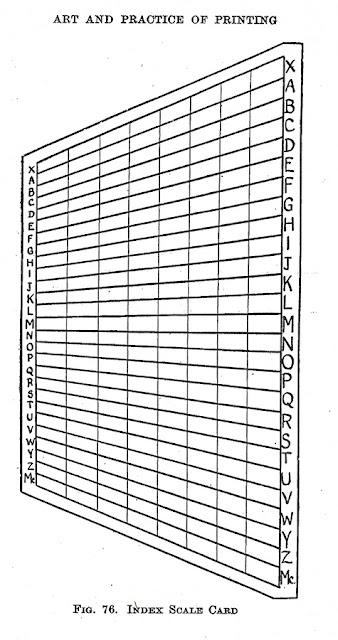

|

Index Scale Card from Atkins, pg 32.

Note "X" at the top and the added "Mc" at the bottom. |

|

Register-Einteilungsschema from Fritz Wiese's Werkzeichnen für

Buchbinder, 1937. Note the combined and added indexing tabs.

We called a Registerkamm where I was an apprentice. Kamm = comb. |

Paul Adams described how to cut these tabs in his Practical Bookbinding (1903) on pages 166-67.

For all such work a thumb index is generally required; each page takes one or more letters, or a specification is given, according to which the binder counts off the number of pages required for each letter—X and Y being here excluded. Nowadays, the indices are cut with index shears, which not only regulates the depth of the index but also avoids the acute angles which are so easily torn in.

Commence cutting from the back, that is, with the Z ; this, being the last letter, is not cut out. Then count off W, cut with the shears, and cut off what remains below to the bottom edge with a sharp knife, to do which a narrow thin board [or sheet of zinc] is slipped underneath. The further you proceed towards A, the longer is the strip which has to be cut out with the knife. When the excisions for the whole alphabet have been made, the letters are pasted on. These are sold ready printed, and nowadays are almost always in one piece for back and front.

The printed sheet with the alphabet is glued or gummed on the back, and, after drying, the alphabet is creased lengthwise and either cut so or punched out with a suitable tool. The single letters are damped and stuck in position.

When cutting with the shears, it is useful to cut a manageable number of pages at a time for comfort, and to keep "round" of the foredge, such as it will be. This cutting, as well as the vertical cut described by Adam above can be done before or after sewing.

Here what the index looks like. Image taken from Mary's copy of Leonard Monk's A Text Book of Stationary Binding, 1912.

|

| The cut out indices. |

Finally, some beautiful images of Mary's German shears, with the final one of them in use.

|

| The brass "clip" at bottom holds the shears closed when not in use. |

|

| View of the shears showing the wide cut on the right. |

|

| The shears in use showing various cut depths. |